Backfilling is a critical process in construction that ensures the stability and longevity of a structure’s foundation. The choice of backfill material is vital, as it affects drainage, compaction, and overall structural support.

Here are the types of backfill materials commonly used in construction projects.

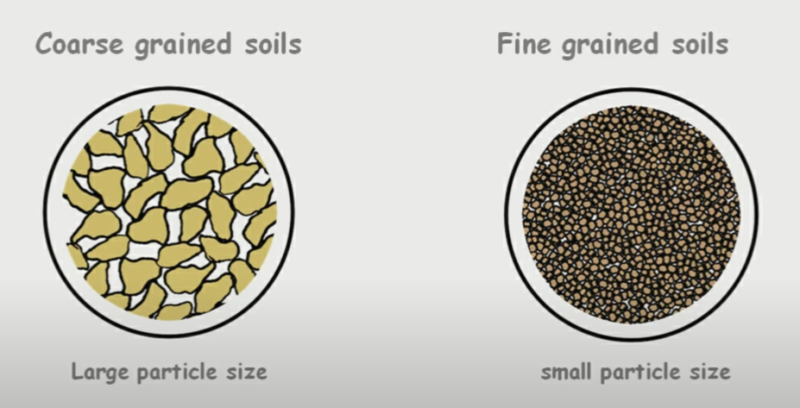

1. Coarse-Grained Soil

Coarse-grained soils, such as gravel and sand, are highly valued for backfilling due to their excellent drainage properties and ease of compaction. These materials are ideal for foundations that require efficient water drainage and stability.

Gravel

Gravel is a preferred backfill material for its strength and ability to support heavy loads. It consists of a mixture of rock fragments, providing substantial structural support. The spaces between the gravel particles allow water to pass through easily, reducing the risk of hydrostatic pressure buildup against the foundation walls.

Sand

Sand is another popular backfill material due to its fine particles, which compact well and provide a stable base for foundations. Sand’s permeability ensures that water can drain effectively, preventing waterlogging and reducing the potential for foundation movement due to moisture changes.

2. Fine-Grained Soil

Fine-grained soils, such as silt and clay, are less commonly used for backfilling due to their poor drainage properties. However, they can still be suitable in certain conditions.

Silt

Silt particles are smaller than sand particles but larger than clay particles. While silt can hold water, it compacts well under pressure, making it a suitable backfill material in areas where moisture control is less critical.

Clay

Clay is known for its ability to hold water and expand or contract based on moisture content. This characteristic can be problematic in some situations, but with proper moisture control and compaction, clay can be used as a backfill. It is important to avoid using clay in areas prone to water accumulation or freezing temperatures.

3. Aggregate Materials

Aggregate materials, including crushed stone and recycled concrete, offer strong support and are often used in combination with other backfill materials.

Crushed Stone

Crushed stone is made from larger pieces of rock broken down into smaller, angular pieces. It is highly effective for backfilling due to its strength and durability. Crushed stone provides excellent drainage and is commonly used in combination with other materials to enhance the overall stability of the backfill.

Recycled Concrete

Recycled concrete is an eco-friendly option that involves using crushed concrete from demolished structures. This material provides good compaction and support while promoting sustainability by reducing waste. Recycled concrete is suitable for various backfilling applications, especially where environmental concerns are a priority.

4. Controlled Low-Strength Material (CLSM)

Controlled Low-Strength Material (CLSM), also known as flowable fill, is a self-compacting mixture of cement, water, and fine aggregate. It is used in situations where high support and easy placement are required.

CLSM is highly flowable, making it easy to place in large excavations and complex geometries. It sets quickly, providing immediate support and stability. CLSM is ideal for backfilling utility trenches, retaining walls, and other areas where traditional backfill materials might be challenging to compact.

5. Rock and Boulders

Rock and boulders are used in backfilling when additional structural support is needed, especially in areas with unstable soil conditions.

Large rocks and boulders are often placed at the bottom of an excavation to provide a solid base. Smaller rocks and gravel are then layered on top to fill the remaining space. This combination ensures maximum stability and prevents the foundation from shifting over time. Rock and boulder backfill is commonly used in retaining walls, foundation bases, and large-scale construction projects.

6. Shale

Shale is a type of rock that can be used as backfill material, but it requires special consideration due to its tendency to break down under certain conditions.

Shale can break down under heavy compaction equipment and slake when exposed to air or water. This behavior means shale must be used carefully, with proper compaction criteria established to ensure it maintains its structural integrity. Shale is typically used in open zones where heavy equipment can operate freely.

7. Marginal Materials

Marginal materials include soils and aggregates that are not ideal for backfilling but can be used under certain conditions to reduce costs or when suitable materials are unavailable.

Marginal materials often include fine-grained, highly plastic soils and expansive clays. These materials are challenging to handle and compact but can be improved with additives like lime or fly ash. The use of marginal materials should be based on thorough testing and consideration of potential long-term impacts on the structure.

8. Commercial By-products

Commercial by-products, such as furnace slag and fly ash, offer sustainable alternatives to natural backfill materials. These by-products can provide excellent compaction and support while promoting environmental sustainability.

Furnace Slag

Furnace slag is a by-product of the steel manufacturing process. It is lightweight, durable, and offers good drainage properties. Furnace slag is commonly used in road construction and as a base material for foundations.

Fly Ash

Fly ash is a by-product of coal combustion and can be used as a lightweight backfill material. It is often mixed with other materials to enhance its properties and provide a stable, supportive backfill. Fly ash is particularly useful in projects where weight reduction is critical, such as filling behind retaining walls.

Importance of Proper Backfilling

Proper backfilling is essential in construction to ensure the longevity, stability, and integrity of structures. It plays a crucial role in supporting foundations, preventing structural damage, and enhancing the overall performance of buildings and infrastructure. Here are the key reasons why proper backfilling is important:

1. Stability and Support

Proper backfilling provides essential support to the foundation, preventing it from shifting or settling over time. By ensuring that the backfill material is compacted correctly and uniformly, the load is distributed evenly, which maintains the structural integrity of the building. Poor backfilling can lead to uneven settling, causing cracks and damage to the foundation and walls.

2. Drainage

Good drainage is critical for preventing water-related issues such as erosion, hydrostatic pressure, and water infiltration. Properly selected and placed backfill materials, like coarse-grained soils, ensure that water can flow away from the foundation. This reduces the risk of water accumulation, which can weaken the foundation and lead to costly repairs.

3. Prevention of Erosion

Backfilling helps protect the foundation from erosion by stabilizing the soil around it. This is particularly important in areas prone to heavy rainfall or flooding, where erosion can undermine the foundation and lead to structural instability. Proper backfilling with materials that resist erosion ensures long-term stability.

4. Protection from Frost Heave

In colder climates, frost heave can cause significant damage to foundations. Frost heave occurs when water in the soil freezes and expands, causing the soil to lift and move. Using appropriate backfill materials and ensuring proper compaction can mitigate the effects of frost heave, protecting the foundation from movement and cracking.

5. Enhanced Load-Bearing Capacity

The load-bearing capacity of the backfill material is critical for the overall stability of the structure. Properly compacted backfill materials like crushed stone or gravel provide a strong base that can support heavy loads without shifting or settling. This is especially important for foundations that bear significant weight, such as those in commercial or industrial buildings.

6. Longevity and Durability

Proper backfilling contributes to the overall durability and lifespan of the foundation and the structure it supports. By using high-quality materials and ensuring proper placement and compaction, the risk of structural issues is minimized, leading to fewer maintenance requirements and a longer lifespan for the building.

7. Cost-Effectiveness

While the initial cost of proper backfilling might be higher due to the use of quality materials and professional labor, it is cost-effective in the long run. Proper backfilling reduces the need for future repairs and maintenance, which can be far more expensive. Investing in quality backfilling at the start of a project ensures a stable foundation that requires less upkeep over time.

Conclusion

Selecting the appropriate backfill material is crucial for the stability and longevity of any construction project. Each type of backfill material has specific properties that make it suitable for different applications. Proper planning, testing, and execution are essential to ensure that the chosen material provides the necessary support and drainage for the foundation.

By understanding the characteristics and best uses of each type of backfill material, construction professionals can make informed decisions that enhance the overall quality and durability of their projects.